FCAW has welds with similar strength to stick welding except in aluminum and dirty or painted material. It's an efficient way of welding professionally and expertly to produce cleaner materials. But stick welding works best for welding dirty metals, while Flux Core is less effective on tainted metal welds but will work well with the ones with a stainless steel body.

Flux core is more effective for large welding jobs, while Stick is better for thicker welds.

What's Better, Stick Welder or Flux Core?īoth are good in their way. The thicker diameter wire withstands windy conditions better. It's better to offer more welding power, deeper penetration, and higher heat. However, some welders can run on inverters provided it produces the current needed.įAQs Which Is Better, 0.030 or 0.035 Flux Core Wire?Ī flux core wire with a diameter of 0.035 inches is better. However, for thicker welds like pipe fencing, trailer flames, and heavy machine repairs, you'll need more input, like a 220 welder.Īlso, a dual-voltage machine running on either 120V or 240 volts can generate that input. So if you have thin metal sheet projects like hinges, a 120-v welder will do. What Input Will I use?Ī welder with 120 volts inputs can give up to 140 amperes maximum, delivering only 1/4-inch welds. This means that you can use them to weld for 6 of every 10 minutes.

Dc flux core welder full#

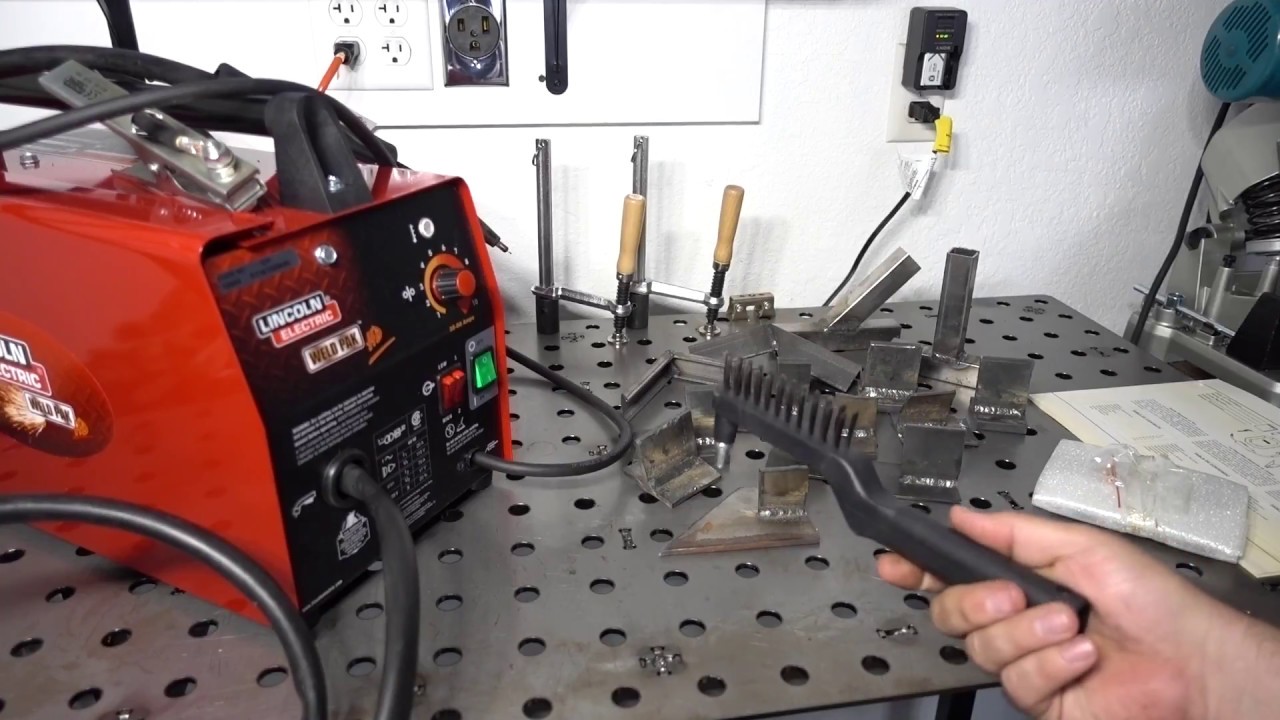

Some FCAW welders used for this process have duty cycles of 60 percent at full power output. Most flux-cored arc welders have a duty cycle of 100%, which indicates they can be used to weld continuously at lower power output. What Is the Duty Cycle for the Flux Core Welder? If you want to run FCAW, most MIG machines will do that just fine because MIG welders are also Flux core welders. That is important because most flux core welders have MIG in their model name, but they need to do a better MIG. But not all flux core welders can run MIG. Will I need MIG, or will Flux Core welding work?.Thus, an investment in a suitable machine will go a long way.īuying Guide for Getting the Best Flux Core Weldersīefore buying a flux core welder, ask yourself the following questions. Therefore, good flux core machines guarantee a higher deposition rate, more stability, and faster welds that don't affect quality.

Dc flux core welder portable#

That's because they can endure the wind and, with a convenient and portable machine, you can weld anywhere. FCAW wires have a self-shielded technique that supports outdoor welding instead of shielding gas, which is ideal for indoor uses. You can weld outdoors and weld thicker metals and thinner materials using the best flux core welders. Why Should You Use a Good Flux-Core Welder? You will need multiple passes for gauges higher than fourteen, which requires a little skill when you use the wire designed for it. How Thick Can Flux Core Weld?įlux core welders can weld thick wire gauges between 22 & 14. But MIG relies on shielding gas for safeguarding the weld. Gasless flux core arc welding requires no shielding gas. So when you pay keen attention to the weld joint, maintaining a good welding angle, welding arc, and movement, there is no big difference. When the welder does an excellent job for flux-core welding and MIG, the flux-core wire produces similar weld strength. There is no noteworthy strength difference between a flux-core weld and a MIG weld.

0 kommentar(er)

0 kommentar(er)